輕鋼別墅設(shè)備、輕鋼別墅龍骨設(shè)備、建材加工設(shè)備、冷彎設(shè)備

聯(lián)系人:梁先生 、吳小姐

手機(jī):13760963229、18029277885

電話:0757-85703327、0757-83100327

郵箱:643981725@qq.com

傳真:0757-85702325

E-mail:zhongherf@126.com

網(wǎng)址:queyyq.cn

地址:佛山市南海大瀝太平?jīng)_表工業(yè)區(qū)西區(qū)8號(hào)

Keel Rollforming Equipment process flow: Decoiler, Rollforming, punching / cutting, product discharge, packaging.

一、Ceiling high-speed 50 keel production line

二、Ceiling high-speed card keel production line

三、Partition wall high-speed 75 vertical keel production line

四、Partition wall high-speed heaven and earth keel production lin

五、Partition wall high-speed 38 through, the main keel equipment technical parameters

TaiZuFrame Equipment Parameters | |||

No. | Name | Quantity | Remark |

1 | automatic decoiler | 1(Set) | Load: 2 tons, the inner diameter of the steel coil is 450-520mm, the outer diameter is 1200mm, hydraulic automatically expanded |

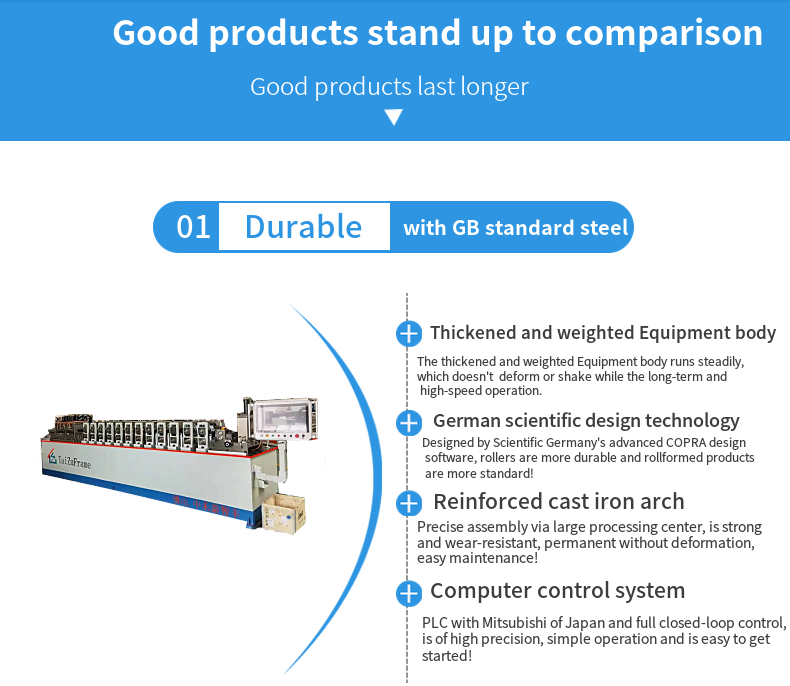

2 | High-precise roll forming equipment | 1(Set) | (1)Rollforming paths: 12 Rollforming paths to mold (including trademark molding, straightening, with rollers) (2)Roll material is Cr12 high-quality die steel, rollers of professional scientific design, the use of CAD / CAM integration technology, through the professional mold processing software automatic programming, the design of the drawings directly downloaded to the CNC lathe finishing processing, to ensure that the roll processing accuracy and professional scientific design drawings to achieve consistency, so as to achieve the molded products with beautiful appearance and standard size. The quality of the equipment is stable. (3)Main motor power: 5.5kw motor (Jiangmen Jiangchen) (4)Product specifications: according to sample (5)Material thickness: 0.25-0.6mm galvanized tape (6)Production line speed: 80m/min (7)Voltage 380V50HZ (8)Hydraulic cuting |

3 | Fully automatic servo non-stop cut chasing | 1(Set) | |

4 |

Punching mold, cutting mold | 1(Set) | Cr12mov die steel |

5 | Automatic baler | 1(Set) | Automatic packing, stacking |

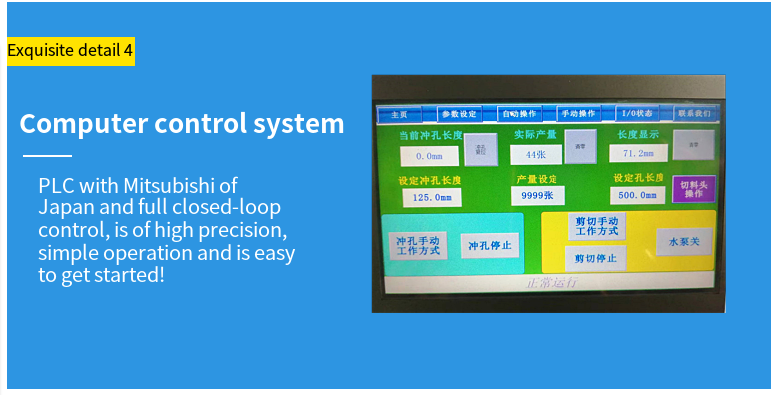

6 | PLC computer control system | 1(Set) | Mitsubishi, Japan |

Production line area: length 25 meters * width 2.2 meters (including automatic baler) | |||

Ceiling high-speed 50 keel production line

Ceiling high-speed card keel production line

Partition wall high-speed 75 vertical keel production line

Partition wall high-speed heaven and earth keel production lin

Partition wall high-speed 38 through, the main keel equipment technical parameters

Light Gauge Steel Frame Roll Forming Machine

light gauge steel frame roll forming machine

Light Gauge Steel Framing Machine

Light Gauge Steel Framing C Purlin Roll Forming Machine

Quality Light Gauge Steel Framing Machine

building material machinery

Light Gauge Steel Framing Roll Forming Machine

C140 Light Gauge Steel Framing Machine

C89 Light Gauge Steel Framing Machine

light steel roll forming machine

steel framing machines

Light Steel Framing Machine

Light Gauge Steel Framing machine

180-2927-7885

13760963229 / 18029277885 |

0757-8570-3327 / 0757-83100327 |

643981725@qq.com |

佛山市南海大瀝太平?jīng)_表工業(yè)區(qū)西區(qū)8號(hào) |